The aircraft and aerospace industry depends on aluminum because it is cost-efficient, flexible, lightweight yet durable, is mechanically stable and manages extreme temperatures well.

1903

The Wright brothers used aluminum to make the engine crankcase for their first wood-frame biplane.

7500 lbs

NASA saved 7,500 lbs by using an aluminum-lithium alloy for the Space Shuttle's Super Lightweight External Tank.

$2.5B

Mars Curiosity Rover mission cost $2.5 billion. The mission would not have been possible without aluminum.

Innovation in Action

In addition to “everyday” applications, aluminum’s strength and durability is also trusted for some of the most extreme uses imaginable – in the sky and even in deep space. Aluminum balances high-strength, low weight and design versatility, meaning it's tailor-made for modern aviation and aerospace. Designers know that aluminum alloys can handle some of the harshest conditions on earth – and beyond.

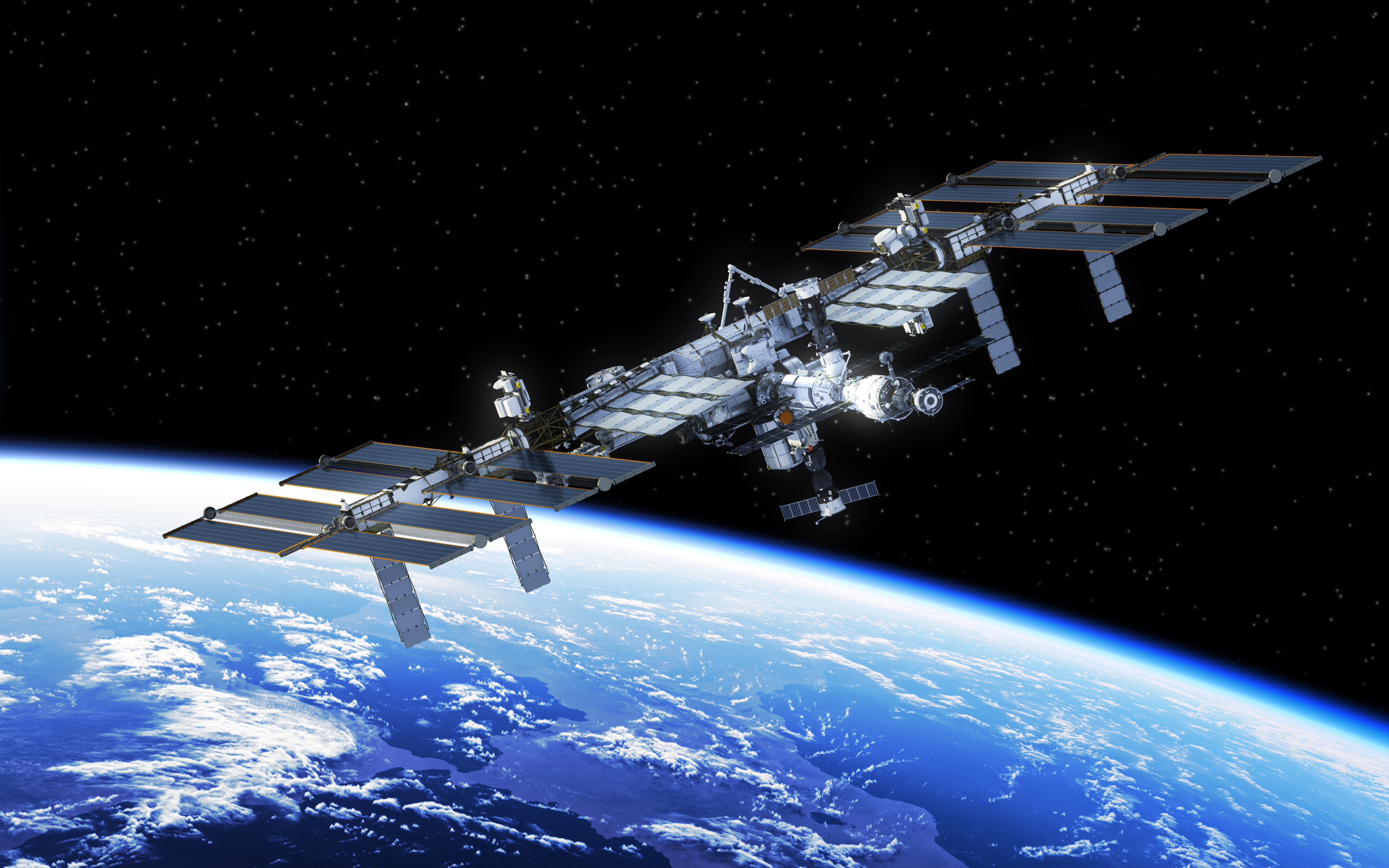

Out of this World

Aluminum is used as building material for space shuttles and other space equipment, but that’s not all. Solid rocket boosters, including the engines on the space shuttle and model rockets, use aluminum as their primary fuel.