Anode Technology a Game-Changer for Aluminum

Revolutionary technology eliminates virtually all direct greenhouse gas emissions from the production of new aluminum. Instead of CO2, the newly devised “inert anode” system emits oxygen during the smelting process.

The Next Generation of Primary Aluminum

Revolutionary technology eliminates virtually all direct greenhouse gas emissions from the production of new aluminum. Instead of CO2, the newly devised “inert anode” system emits oxygen during the smelting process. (The electric energy that runs through an anode is what enables aluminum smelting). This game-changing innovation has the potential to make aluminum – already one of the most sustainable materials on the market today – even greener.

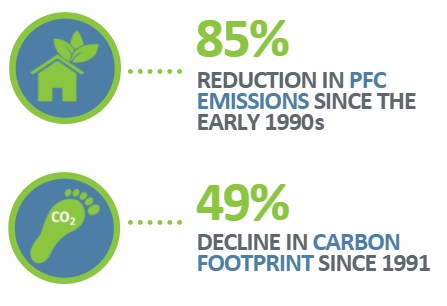

Already, primary aluminum production in North America is cleaner today than it has ever been. Since 1991, the carbon impact of primary aluminum production in the U.S. and Canada has declined by nearly half thanks to voluntary efforts by the industry to reduce emissions, technology control improvements and increased regional reliance on renewable hydropower as an energy source.

Industry Steps Up for a Cleaner Future

Innovations by Aluminum Association members like Alcoa and Rio Tinto – engaged in a joint venture developing the Elysis inert anode technology – has attracted investors like Apple and the government of Canada. If fully implemented in Canadian smelters, the technology could eliminate 6.5 million tonnes of greenhouse gases every year – the equivalent of taking 1.8 million cars and trucks off the road.

Aluminum is already a material tailor-made for a more circular economy. The metal makes cars and trucks more energy efficient, buildings greener and packaging more recyclable. Inert anode technology is the next step leading aluminum to an even more sustainable future.